Automated Gluing Locator by ITW:

Transform Your Wire Harness Production

Tackling New Challenges with Cutting-Edge Automation

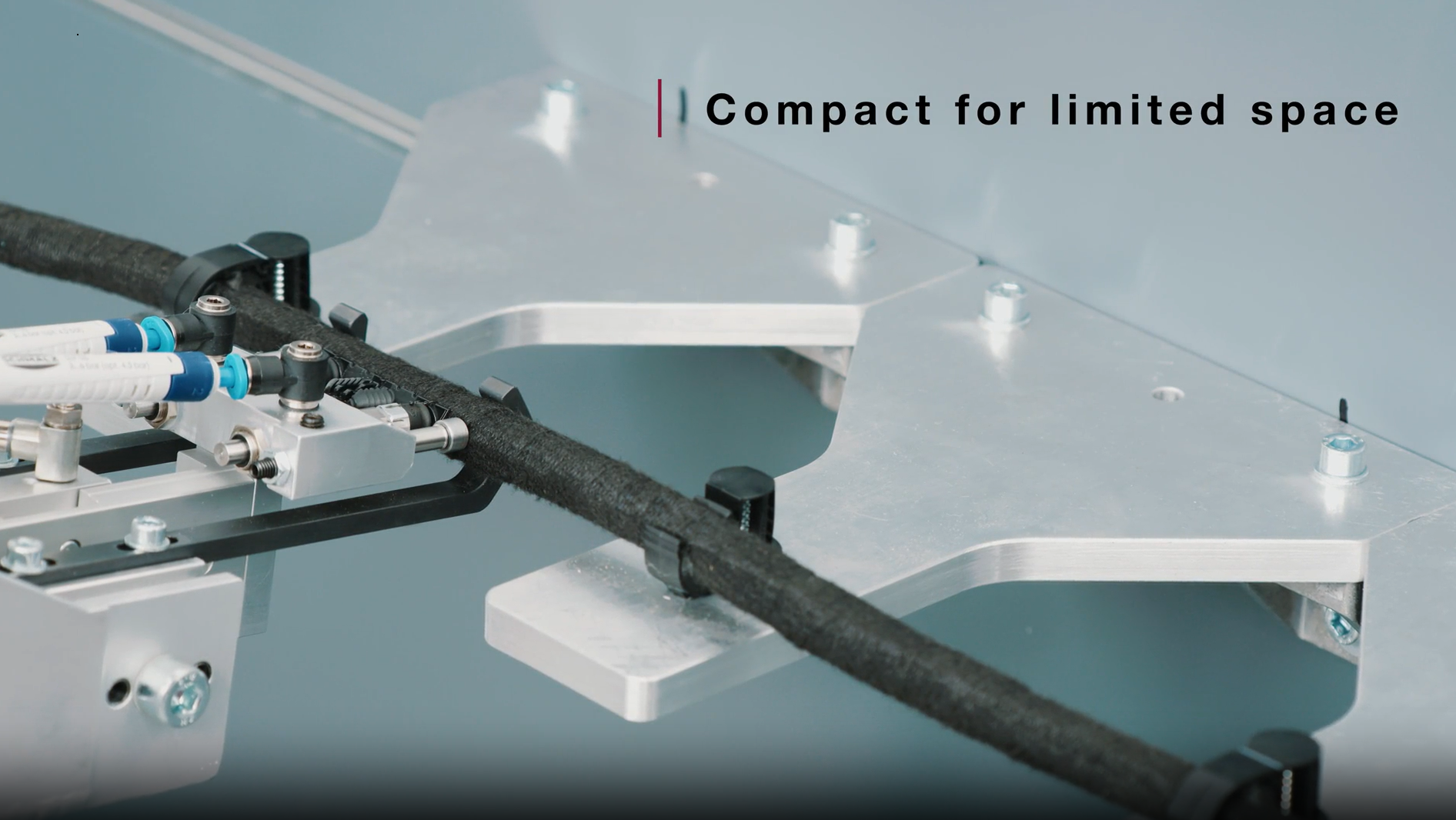

With wiring systems growing increasingly complex and error-prone of the manual production, the new DIN72036 standards bring heightened demands for traceability and process design. ITW’s Automated Gluing Locator offers a comprehensive solution, enabling you to seamlessly integrate automation into your wire harness assembly processes, simplify complexities, and meet rigorous procedural demands.

Your Complete Automated Assembly Solution

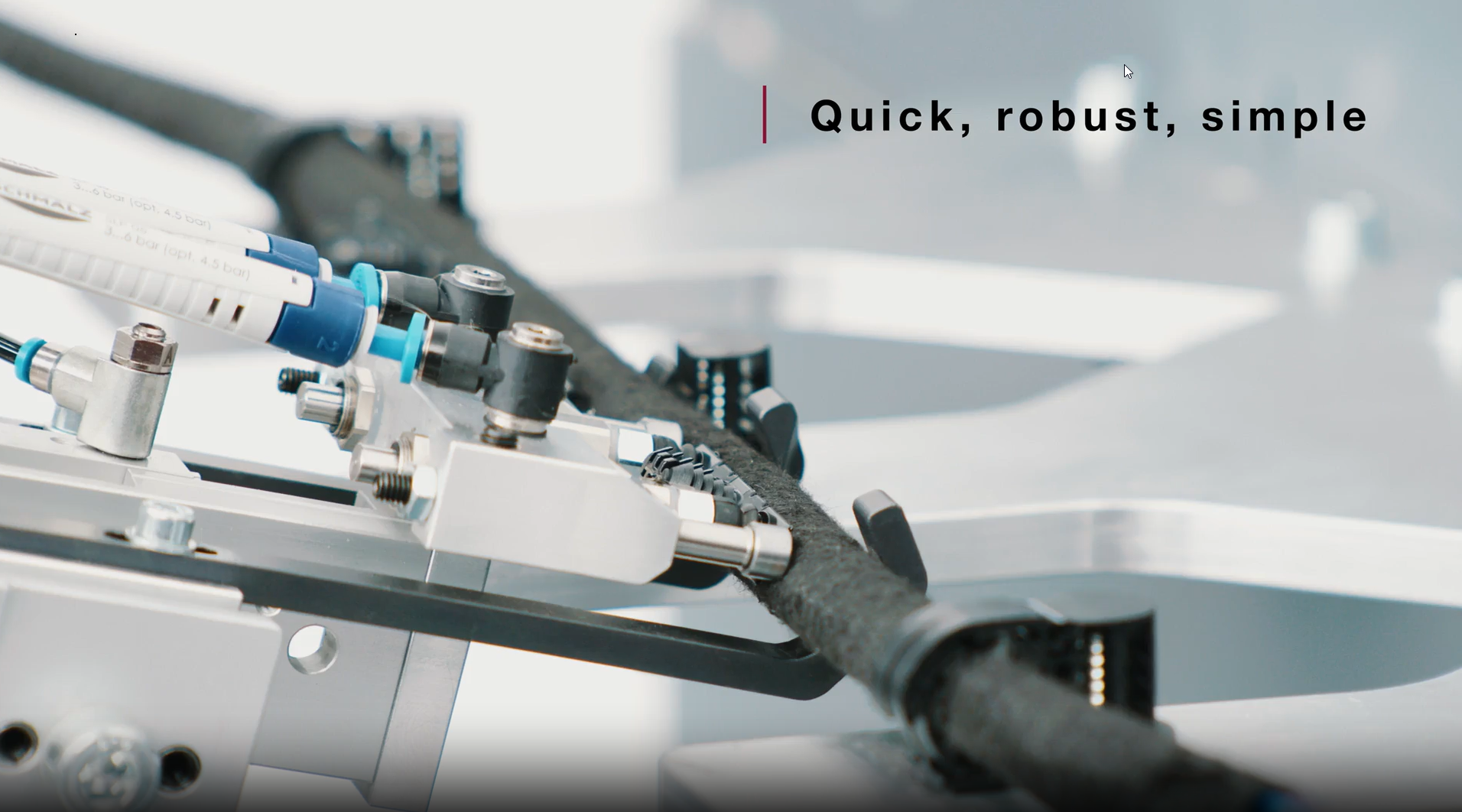

We deliver a total solution including locators, expertise, and integration support. Compatible across all locator variants, ITW’s sethead works flawlessly with IWOD Hotmelt Adhesive to ensure strong bonds with all standard tape materials except PVC. The flexible adjustable and extendable automation concept standardizes and optimizes your processes.

Fast, Reliable, and Fully Automated

The Automated Gluing Locator allows for direct adhesive application of wiring fasteners to harnesses, offering a retention force up to 600 Nm. Bonding occurs in just a fraction of a second with immediate hardening, streamlining your production line.

See Our Technology in Action

Get a firsthand look at the capabilities and performance of the Automated Gluing Locator.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationKey Benefits of the Automated Gluing Locator:

-

Automates complex processes completely

-

Simple and robust process

-

360° access to wire harness

-

Standardizes fasteners, reduction of the number of fastener variants

-

Lowers overall production costs through localized manufacturing

-

Strengthens supply chain resilience

Experience the Automated Gluing Locator Live

Visit our Enkenbach facility to witness the Automated Gluing Locator in action and see firsthand how it can revolutionize your production. Contact your dedicated sales representative or use our online contact form to arrange a live demonstration.